LOVELL, the leading provider of innovative residential developments, has become the first house builder to take proactive steps in a bid to tackle the challenge of asbestos waste.

Asbestos still poses a major challenge to the housebuilding industry where it is still sent directly from site to landfill for future generations to tackle. Lovell has been the first to act, collaborating with Thermal Recycling to safely package and convert asbestos waste into a safe and reusable cement substitute.

Lovell completed a pilot project under a licence from the Environment Agency with Thermal Recycling, who were assisted by its research partners at Wolverhampton University. The trial was a complete success and saw 25 tonnes of asbestos removed from three demolished buildings at Lovell’s Castleward development in Derby city centre.

Steve Jones, regional health safety and environmental manager for Lovell Midlands, said: “We have made a commitment to move towards reducing the amount of asbestos going to landfill. As such, this was an important environmental initiative for us to trial with Thermal Recycling and one that has proven that it is possible to solve the problems asbestos poses to the industry and future generations. This is a great step in our approach to circular economy, ensuring materials are recycled and reused rather than taken to landfill.

“One of the reasons that asbestos waste continues to be sent to landfill is hesitance from the industry to change processes and practices. Our demolition partners have confirmed this, and we’re pleased they had a similarly positive experience.”

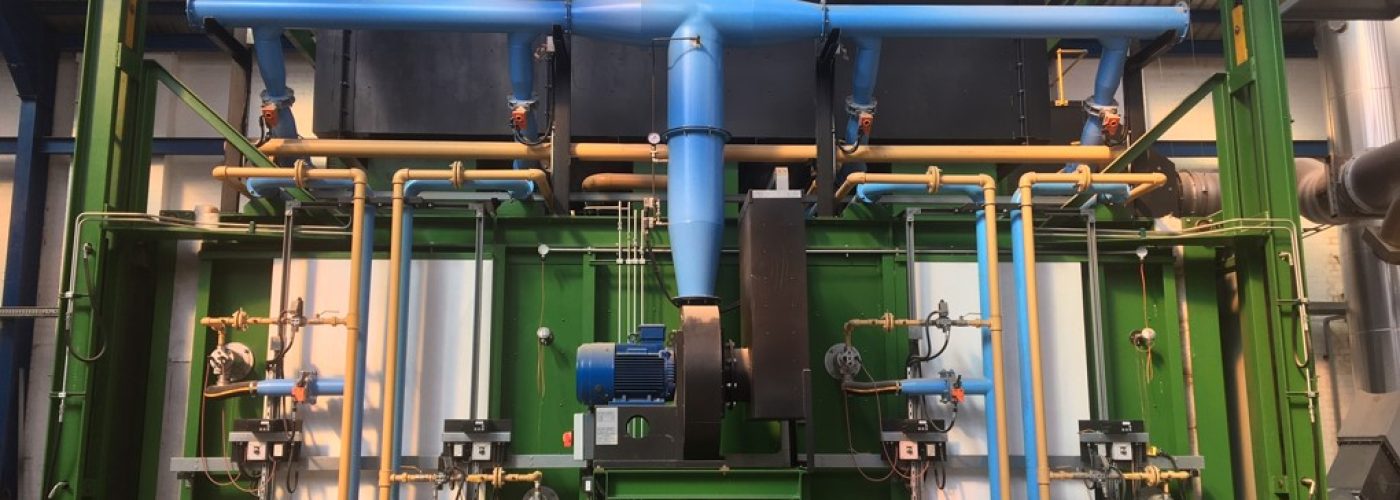

Opened in September 2020, Thermal Recycling currently operates from a demonstration plant in Wolverhampton and has a licence to treat up to 30,000 tonnes of cement bonded asbestos each year when their full-scale plant is built. The asbestos is treated using the latest developments in thermal technology to change its composition to make it safe. The cement is stripped by a state-of-the-art kiln and turned into a sustainable aggregate for use as a building material.

Graham Gould, chairman of Thermal Recycling said: “Thermal Recycling is delighted to be working with a Lovell and their contractors. They have all recognised that there is now a viable alternative to sending asbestos to landfill and have the determination and commitment to embrace that change.”

Steve continued: “Lovell is committed to making the necessary changes to ensuring its removal is safe and environmentally friendly. Lovell has a target of recycling 100% of its asbestos waste which we are delighted to be working with Thermal Recycling to achieve through further schemes in the future.”

For more information, please visit https://www.lovell.co.uk/