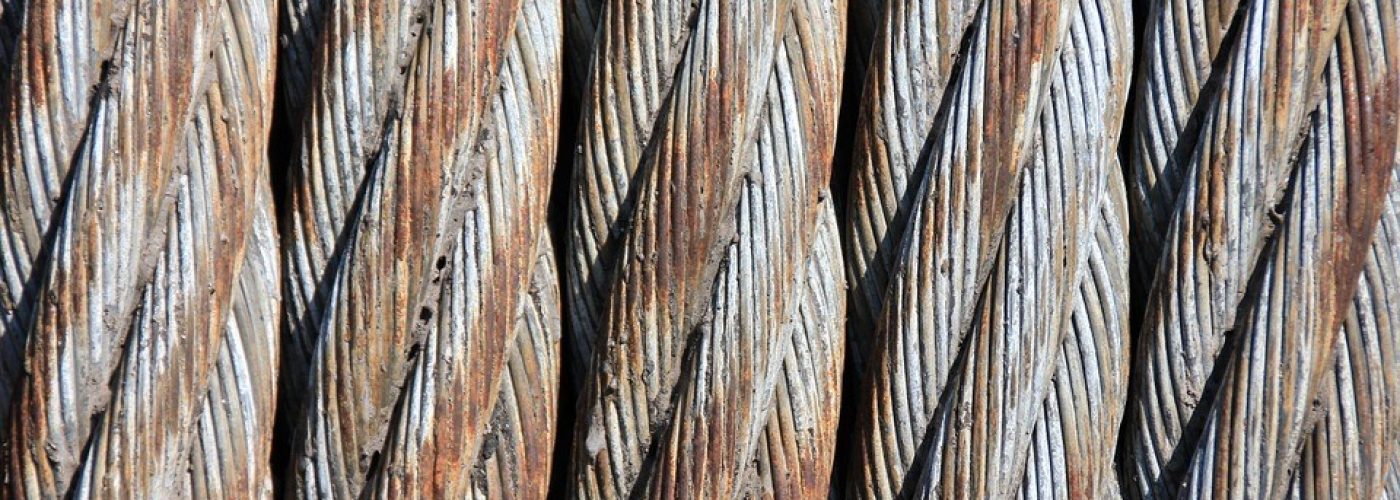

Rigging machines like cranes use various components to operate, including a wire rope. Proper choice, installation, use, and maintenance are essential to keep the rope in top condition for a longer time. However, even with appropriate care, it will eventually reach its end of life, as it’s still an object prone to natural wear and tear.

There are various causes of wire rope damage, and you must be familiar with them as a crane owner. It helps determine an issue on the first sign and act on it immediately before it leads to failure. Neglecting it may cause injuries, property damage, and delay in the business operation. Check out some of the common causes of wire rope problems below.

Abrasion

Improper wire contact to the drum, sheave or other objects can cause abrasion damage. Other causes include incorrect rope size, wrong fleet angle, poor spooling, and frozen rollers. Signs of this damage are worn ends as thin as the edge of a knife. Prevent this problem by ensuring proper installation and using the right wire rope size.

Corrosion

You would see the corroded part externally, but it would be hard to tell the extent of the damage through the naked eye, thus making it more dangerous. Some of the causes of corrosion damage are improper lubrication, exposure to substances like acid, and improper storage. Store equipment appropriately and ensure proper lubrication to prevent corrosion on wire rope. If you want to ensure that it is still safe for use, consult an expert like a service provider specialising in PM, ATLAS, and Hyva cranes. If the rope needs replacement, they can also advise the right one to use and help with proper installation.

Fatigue

The repetitive rubbing of the wire rope on the sheave and drum could cause damage due to fatigue. It’s one of the easiest to detect because you can immediately see it with your naked eyes. Individual wires would break, making them weak and eventually affecting the other wires, then leading to failure. Excessive rubbing may be due to vibration, worn bearings, and incorrect rope diameter. Prevent these issues to avoid premature failure due to fatigue.

Kinked

The kinking of wire ropes could be due to improper unreeling of the rope, incorrect sheave size, and poor rope installation. Be sure to choose the correct sheave size that matches your rope. Moreover, ensure that you unreel and install it the right way. Looped wires also have similar causes.

Tension

Carrying a load more than its capacity can cause the wire rope to break due to tension. You will see cuts on the individual wires on one end. Consider the load limit of the rope, and ensure that you stay within that limit to extend its life.

Core protrusion

This is characterised by the rope’s core protruding out. One of its causes is unwanted rope twists, which may occur with improper installation. Poor seizing methods and shock loading are also other possible causes.

Keep your wire rope in check for any damage, and fix or replace it as needed to ensure safe operation.